HBH-9820 Brochure

Buying Points of the Machine:

Better shaped button holes due to the thread tension

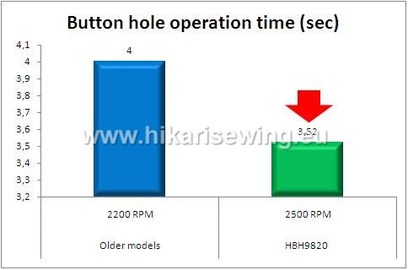

The HIKARI innovative electronic eyelet button holer forms the buttonholes with higher precision due to the servo drive system, and better controlled thread tension. No matter what kind of thread is used, the possibility of stitch dropping is dramatically decreased, therefore the value of waste decreased as well, and higher efficiency is reported during production. 12% higher production output due to the shortened production time

HIKARI HBH-9280 innovative electronic eyelet button holer machine’s structure is adopted to high speed operation. Due to the installed servo motor, the sewing speed is increased to 2500rpm. The higher speed together with the structural modification of the mechanic elements offers ~12% less production time on a 22mm long buttonhole. This fact gives ~12% higher productivity during serial production and offers a significant increase on the profitability of the manufactured product. Central lubrication system

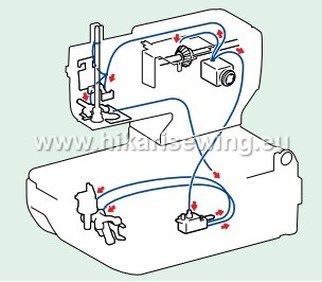

The machine is equipped with a central lubrication system, which offers as minimum oil leaks on the garments as possible. The oil is placed in a central reserve, and has been pumped to the contact place on small diameter pipelines and wicks. The lubrication monitoring gauge is installed on the side of the machine which is easy to observe. Waste material collection system

The machine is equipped with a with a special waste fabric transfer system, which is able to collect the residual fabric after the cutting procedure of the button hole. The system operated with compressed air, prevents the scattered fabric pieces and keeps the work environment clean for the operator. |

HIKARI HBH-9820 Series

| ||||||

HBH-9820

Electronic Eyelet Buttonholer Machine