H9180N-7C-5/AK Brochure

Minor oil lubrication technology

Minor oil lubrication technologhy (dry needle -bar), greatly reduces oil pollution risk. H9180N adopting dry machine head of semi lubrication technology, accomplished the needle bar without oil and hook with semi oil, avoid the leakage while machine running, this preventing the accurence of the phenomenon of oil soiled fabric. So the quality is improved. Direct-drive servo motor, saves power 60-70%

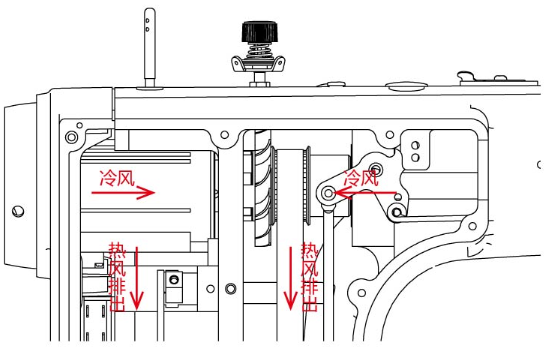

H9180-7C direct-drive servo motor, greatly reduce transmission usage and no belt. Easy to operate, H9180N internal optimization design, improve the machine transmission efficiency. This make the whole machine reach the purpose of energy saving and enviromental protection. Built - in the head control box with internal turbine cooler

The state of the development and the commitment of HIKARI can be seen here: currently on the world the HIKARI H9180N, the H8800D and the JUKI DDL8700A machines has built-in the head control box. In the next years the other manufacturers will follow us, because this construction offers less malfunction and lower maintenance time and cost for the users. Built-in the head LED light for more precise work and better ergonomy

The LED light is built together with the reverse switch. It is integrated to the machine head for better clearance of the movements of the operator. The LED unit is equipped with 14 LEDs, and it is adjustable in 5 levels to work easier with reflective materials. |

H9180N-7C-5/AK

| ||||||

H9180N

World’s first highly integrated computerized direct-drive lockstitch machine with dry needle bar, auto thread trimmer, auto backstitch, thread clip device and auto foot lifter.