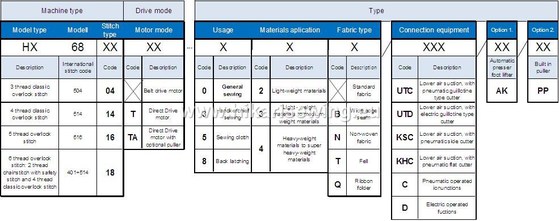

HX6800TA-UT/AK Brochure

Computerized Direct Drive Motor

HIKARI designed, and patented the world’s first direct drive overlock in 2007. The use of the maintenance free direct drive motor offers 14,6 % higher efficiency, and 66 - 71,5% less power consumption compared to clutch motor equipped machines. HIKARI is the leading sewing machine manufacturer in the field of innovation with a biggest experience in direct drive technology, which makes bigger profit in your production site. Built-in the head puller for better fabric transport

With the built in puller it is available to set up the feed of the fabrics with better accuracy. It is possible to adjust electronically the timing and the duration of the puller operations, at the beginning and at the end of the sew process, and mechanically the push force and the speed of the puller compared to the differential feed device. This system even allows to stretch the fabrics in case it is needed. Built - in the head LED light for more precise work and better ergonomy

The LED light is built over the working area, together with the manual chain cutter switch. It is integrated to the machine head for better clearance of the movements of the operator. The LED unit is equipped with 9 LEDs, and it is adjustable in 9 levels to work easier with reflective materials. Full computerized user friendly control panel

Full computerized, easy to use, user friendly control panel. The functions are grouped, and distributed according to the needs of the operator. The position of the functions are clearly separated, which helps the operator to use it faster to save time, and increase the efficiency. The functions can be set up with the help of the LCD screen. |

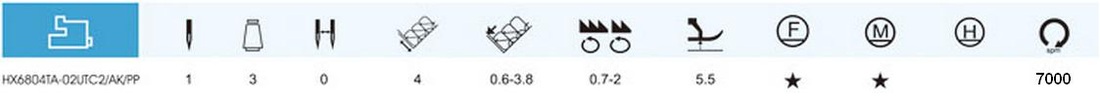

HX6800TA-UT2/AK Series

| ||||||

HX6800TA-UT2/AK

Direct Drive Innovative Noiseless and Power Saving Technology, Super High-Speed Overlock Series with Integrated LED Lights

Automatic - Semi-Automatic - Manual Functions

Chain Cutter with Auto Short & Silent Suction Safety Systems