Buying Points of the MachineThis super high-speed overlock machine, with advanced technology and special insight, intelligent direct-drive auto trimmer with many patents. Comparing with traditional belt driving overlock machine, improving efficiency 14.6% ,it saves 60-71% of the power, decreasing the intensity of labour 30%, will guide future trend and create brilliant value for customers.

Computerized Direct Drive Motor

HIKARI designed, and patented the world’s first direct drive overlock in 2007. The use of the maintenance free direct drive motor offers 14,6 % higher efficiency, and 66 - 71,5% less power consumption compared to clutch motor equipped machines. HIKARI is the leading sewing machine manufacturer in the field of innovation with a biggest experience in direct drive technology, which makes bigger profit in your production site. Built - in the head LED light for more precise work and better ergonomy

The LED light is built over the working area, together with the manual chain cutter switch. It is integrated to the machine head for better clearance of the movements of the operator. The LED unit is equipped with 9 LEDs, and it is adjustable in 9 levels to work easier with reflective materials. |

HX6800TA

|

HX-6800TA

Direct Drive Innovative Noiseless and Power Saving Technology

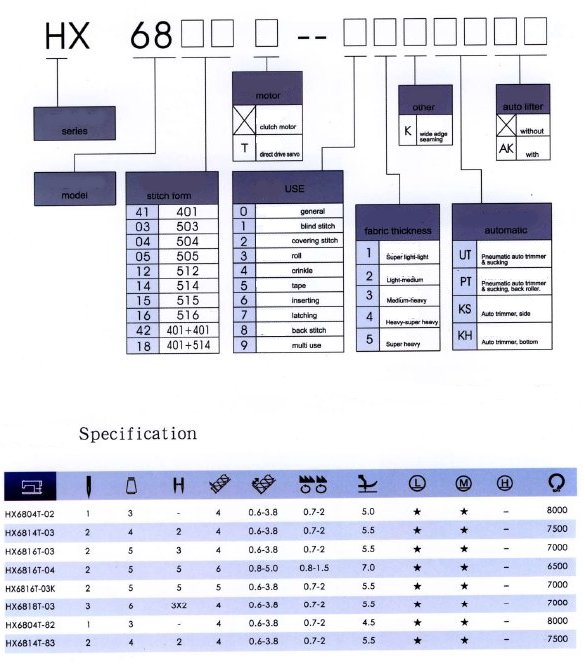

Super High-Speed Overlock Series

with Integrated LED Lights