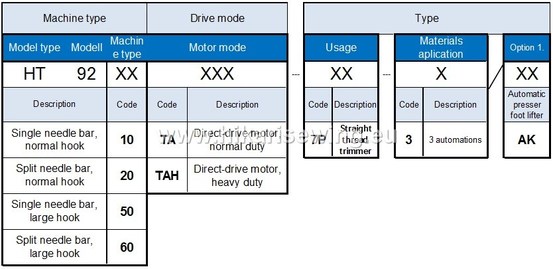

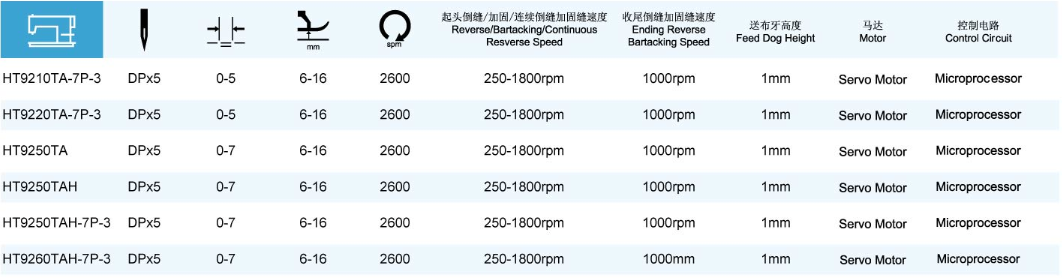

HT9200TA-7P-3 Brochure

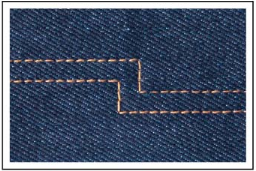

Split needle bar to sew complete corners

During normal production both of the needle bars are working. In case the operator would like to form a corner, each of the needle bars can be switched off with the quick split needle bar actuation switch, which is placed on the front side of the machine. After the corner has been finished the disengaged needle bar can be switched back to work. With the help of this device, the operator can sew difficult formations like complete corners with the double needle lockstitch machine. Straight knife thread trimmer for better flexibility

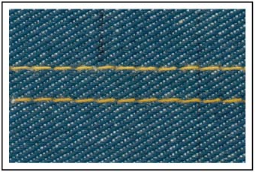

HIKARI redesigned the flexible straight knife thread trimmer system, to improve the flexibility of the double needle lockstitch machines in production. The system is equipped with easy to exchange larger capacity bobbins to achieve better efficiency. The machine is equipped with a standard 6.4 mm needle gauge set, and HIKARI offers a wide variety of gauge conversion sets from 3.2 mm to 25,4 mm for both normal and heavy duty machine variants. Built - on the head LED light for more precise work

The LED light is built together with the reverse switch. It is mounted to the machine head for better clearance of the movements of the operator. The LED unit is equipped with 10 LEDs, and it is adjustable in 5 levels to work easier with reflective materials, and provides better visualization for the operator. |

HT9200TA-7P-3/AK

| ||||||

HT9200TA

Double Needle Direct Drive Lock Stitch Machines with Automatic Thread Trimmer and Integrated LED Lights