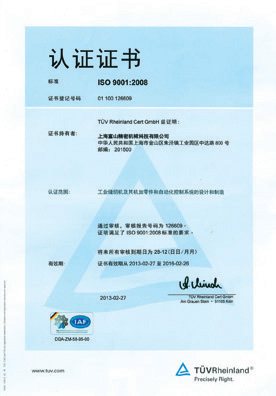

In February, 2013, HIKARI Shanghai precision machinery technology co., LTD. (referred as the HIKARI below) passed ISO9001:2008 quality management system requirements and obtained the German TUV rheinland (Shanghai) issued by the ISO9001:2008 quality management system certification (certificate of registration number of 01, 100, 126609) with the certification scope: industrial sewing machines and machining parts and manufacturing, and automation control system design. The certificate is valid from 2013-02-27 to 2016-02-26.

According to ISO HIKARI company director Zhouqiao first introduced: "Abnormal strict ISO9001:2008 quality management system audit, at the same time to the company's benefits, it is not only to the company internal operation standard certification, but also an inspection on the quality of products. The certification is mainly from the four stages which involves the main content of the internal management system, the quality control of product development, project implementation process and after-sale technical services, etc.

First of all, enterprise own quality system identification, diagnosis phase. Toyama company established in accordance with industry standards, close to the international standard of consulting, research and development, implementation, after-sales service standards, and through this round of the outline of the clear operation system, to adapt to the international standard.

Second, set up perfect quality system manual stage. Through several stages of planning, specification, set out for company operation, in line with the international and domestic standards of quality system manual, clear the quality of the company operation system.

Again, test run and perfect one phase review. Quality system commissioning, discovery, improvement is not clear, in the work of the past problems, through repeated training, practice, internal audit evaluation link in operation and consulting experts, established the system's normal operation, certified professional access to the company for a stage of the audit.

At last, the second stage audit and data verification. Through a stage audit improvement, toyama company has established a relatively complete quality management system, the research and development of project management, implementation, management, after-sale service projects such as operating standards, rules have been implementation. Experts on the two-phase execution records, authority records for verification, review carefully, and put forward correcting to insufficient part.

After a long trial run, and constantly improve and other departments actively cooperate with, the company successfully passed the ISO9001:2008 quality management system certification. Believe under the opportunity, toyama company will going to adhering to the company "active and enterprising, learning, innovation" concept, the practice of technology innovation, strict quality requirements, to the internationalization, high standards.

First of all, enterprise own quality system identification, diagnosis phase. Toyama company established in accordance with industry standards, close to the international standard of consulting, research and development, implementation, after-sales service standards, and through this round of the outline of the clear operation system, to adapt to the international standard.

Second, set up perfect quality system manual stage. Through several stages of planning, specification, set out for company operation, in line with the international and domestic standards of quality system manual, clear the quality of the company operation system.

Again, test run and perfect one phase review. Quality system commissioning, discovery, improvement is not clear, in the work of the past problems, through repeated training, practice, internal audit evaluation link in operation and consulting experts, established the system's normal operation, certified professional access to the company for a stage of the audit.

At last, the second stage audit and data verification. Through a stage audit improvement, toyama company has established a relatively complete quality management system, the research and development of project management, implementation, management, after-sale service projects such as operating standards, rules have been implementation. Experts on the two-phase execution records, authority records for verification, review carefully, and put forward correcting to insufficient part.

After a long trial run, and constantly improve and other departments actively cooperate with, the company successfully passed the ISO9001:2008 quality management system certification. Believe under the opportunity, toyama company will going to adhering to the company "active and enterprising, learning, innovation" concept, the practice of technology innovation, strict quality requirements, to the internationalization, high standards.

RSS Feed

RSS Feed