HMS-1310 Series Brochure

Buying Points of the MachineFour kind of sewing area size depending on the customers needs:

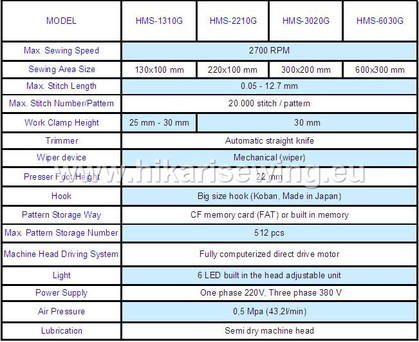

Sewing Area Size: HMS-1310G pattern sewing machine (13cm*10cm) HMS-2210G pattern sewing machine (22cm*10cm) HMS-3020G pattern sewing machine (30cm*20cm) HMS-6030G pattern sewing machine (60cm*30cm) Machine Types: HMS-1310G-01S (13cm*10cm, electric, heavy duty) HMS-1310G-01A (13cm*10cm, pneumatic, heavy duty) HMS-1310G-02S (13cm*10cm, electric, medium heavy duty) Quick pattern upload with memory card

On the HIKARI innovative pattern sewing machine there are two ways to upload your patterns, with a CF memory card through the CF memory card reader which you can find under the machine, or with the optional pattern editor, which we can use to write our own patterns and we can upload them to the built in CF card reader. The upload of the patterns is quick, user friendly and easy. In the machines memory, we can store up to 512 patterns and we can easily copy the patterns with the help of the CF memory card. With the use of the optional pattern making software (PS-300BD) we can easily edit or change the patterns. |

HMS-1310 Series

| ||||||

HMS-1310 Series

Computerized Direct Drive Heavy Duty Pattern Sewing Machine, Electric or Pneumatic Type

Velcro Sewing, Label Sewing, Automobile Industry Automatization, Ideal To Sew Small Size Parts